Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

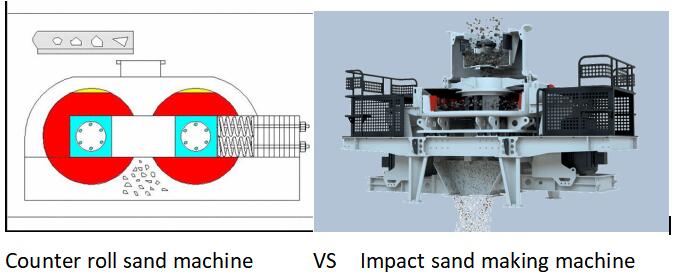

1.Contra-Roll crusher is also called counter-roll sand making machine and counter-roll sand making machine. Its discharge particle size is relatively fine, and it is often used in sand making operations. It is suitable for feeding particle size less than 80mm and finished product particle size requiring 50 mesh. -20mm fine crushing operations, such as cobblestone, iron ore, quartz stone, etc., belong to the processing scope of the Roller sand making machine. The roller sand making machine has been in existence for a long time. In the development process, various models have been developed to meet different production needs.

| Model | 2PG0425 | 2PG0640 | 2PG0740 | 2PG0850 | 2PG1060 | 2PG1260 | 2PG1560 |

| Roll Diameter (mm) | Ф400 | Ф600 | Ф700 | Ф800 | Ф1000 | Ф1200 | Ф1500 |

| Width Of Roll(mm) | 250 | 400 | 400 | 500 | 600 | 600 | 600 |

| Feed Size (mm) | ≤25 | ≤25 | ≤25 | ≤25 | ≤30 | ≤30 | ≤30 |

| Discharging granularity mm) | 2-8 | 2-8 | 2-8 | 2-8 | 2-10 | 2-10 | 2-10 |

| Capacity (t/h) | 5-10 | 10-20 | 15-30 | 20-40 | 30-50 | 40-70 | 60-110 |

| Motor Type | Y132M-6 | Y180L-6 | Y200L-4 | Y225M-4 | Y250M-4 | Y315M-6 | Y315L-6 |

| Power(kw) | 5.5×2 | 15×2 | 30×2 | 45×2 | 55×2 | 75×2 | 110×2 |

Performance advantages:

(1) No screen bar design, not easy to block

The roller sand making machine adopts a screenless design, which can process various forms of materials such as dry and wet, which is not easy to block and has high sand making efficiency.

(2) The particle size of the finished product is uniform and the powder passing rate is low.

The processing process is simple and fast, the number of times of material hitting is small, and the finished product produced by the roller sand making has uniform particle size, low over-crushing rate, and low needle flake content, which meets the standards for construction use.

(3) The size of incoming and outgoing materials can be adjusted, which is more flexible

The size of the incoming and outgoing materials can be adjusted by the wedge or gasket adjustment device between the two rollers, and the hydraulic Cylinder is also equipped with a hydraulic cylinder that can automatically retreat and recover when encountering materials that are difficult to break, and the failure rate is significantly reduced.

(4) The price is favorable and cost-effective

The output of the roller sand making machine is small, it belongs to the small and medium-sized sand making equipment, the price is relatively low, the investment cost is relatively small, and the initial capital pressure will be relatively small.

2.Impact sand making machine

Production capacity: 40-650t/h Feed particle size: ≤55mm

Discharge particle size: 0.25-5mm Working principle: Stone hits stone and stone hits iron

Performance advantages:

(1) Low cost and long service life

The combined throwing head only needs to replace the worn part, which can reduce the use cost by 30%; the peripheral guard can be turned up and down to prolong the service life

(2) High crushing efficiency and strong crushing capacity

The impact sand making machine has high sand making efficiency, and the deep cavity impeller design increases the throughput of the whole machine by more than 30%, the material passing rate is high, and the production capacity is strong.

(3) The product has good particle shape and uniform particle size

The impact sand making machine is very suitable for the production of fine sand. It can not only make sand but also has a shaping effect.

(4) Green environmental protection, low pollution

The impact sand making machine is optimized for the sealing of the crushing chamber, coupled with the self-circulation of the air flow inside the vortex chamber, plus the pulse dust collector and the noise eliminator, it can achieve green sand making.

In fact, although both machines can make sand, according to the above comparison and analysis, we can see that the difference between the two is quite big. The roller sand making machine is more suitable for small sand making production lines, and the price is cheaper; impact The effect of artificial sand making is better, but at the same time the price is slightly higher. In a word, no matter which equipment you use, it still needs to match your production needs. Choosing a suitable production equipment can make you more effective with less effort.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.