Reinforced kevlar Edge Corrugator Belt

$130≥10Square Meter

| Payment Type: | L/C,T/T,Paypal,D/A,D/P |

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP,DEQ,DDP |

| Min. Order: | 10 Square Meter |

| Transportation: | Ocean,Land,Air |

| Port: | Tianjin,Beijing,Dalian |

$130≥10Square Meter

| Payment Type: | L/C,T/T,Paypal,D/A,D/P |

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP,DEQ,DDP |

| Min. Order: | 10 Square Meter |

| Transportation: | Ocean,Land,Air |

| Port: | Tianjin,Beijing,Dalian |

Model No.: Woven Belt with Kevalr Edge

Brand: HUATAO

Model NO.: Corrugator Belt

Tensile Strength: Strong

Air Permeability: Excellent

Moisture Absorption: Excellent

Machine Speed: 100-400m/Min

Reinforced Kevlar Edge: 100mm-400mm

Thickness: 8.5mm,9mm,10mm

Seam: Clipper with Rubber Coated/Hot Jaw Lacing

Specification: Width: 1400mm - 3200mm

Application: Automatic Corrugator Line

| Selling Units | : | Square Meter |

| Package Type | : | Waterproof film+Dampblanket+Plasticbag+pallet |

The file is encrypted. Please fill in the following information to continue accessing it

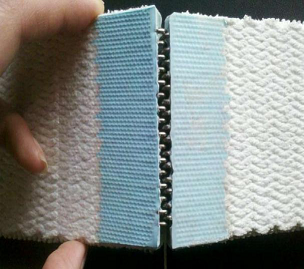

Reinforced kevlar Edge Corrugator Belt

Corrugator Belts Descripation

When the corrugated board production line is running,due to the Corrugator Belt with the hot plate touching directly, so the surface temperature of Corrugator Belts -9mm will be rise 40% than original temperature, In order to improve the temperature and wear strength of the belt, the edge of corrugator belt will be weaving high temperature and wear-resistant special fiber: Aramid fiber. while ensuring the performance of the belt, also greatly enhanced resistance to wear and Abrasion resistance. High Speed Corrugator Belts also called Synthetic Corrugator Belts.

Corrugator Belts Feature

1. Suitable as top belt with high speed (above 150m/min ) production

2. Heat and Super tear resistance

3. Inwoven Aramid edge to reinforce the belts ,reduce wear substantially and ensure a longlife time .

4. Particularly for frequent changes of board width

5. More Popular in the all corrugators plant.

Different Joint For Corrugator Belt

Hot Clipper Lacing With Flocking Clipper With Rubber Coated

How To Cleaning Maintenance Of Corrugator Belt?

It is better to thoroughly clean the corrugator belt once time per month.

Here are some detail steps:

1. Keep the machine running with slow speed;

2. Make the corrugator belt fully moist by water or low pressure steam spray with much water content;

3. Put into some detergent and clear up the dirt & paste scar with soft brush;

4. After cleaning,using water to wash the belt again;

5. During the washing process,it will be greatly help to lay out shallow U-shaped iron plate or shallow groove under the corrugator belt. It will make the cleaning water flow out to the machine outside, keep the heating panel clear and no any corrosion;

6. When necessary, you can turn on steam to heat the heating panel and make the wet corrugator belt drying with slow speed.

Related Accessories About Corrugator Belt

Fastener Clipper

30cm length Per Pc One Box With 12 Pcs

Corrugator belt threading (Connecting pin) Manual Clipper Machine

our Huatao Group can also supply other releated Corrugator Machine and Spare Parts:

Corrugating Rolls: Chrome Plated Corrugating Roll / Tungsten Carbide Corrugating Roll

Single Facer: Cassette Single Facer / Fingerless Single Facer

Slitter Cutting Blade

Spray Humidifier

etc

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.