Durable Sludge Transfer Screw Pump

$1200≥1Set/Sets

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW,CPT,CIP,DAF |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shanghai ,Qingdao, Tianjin |

$1200≥1Set/Sets

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW,CPT,CIP,DAF |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shanghai ,Qingdao, Tianjin |

Model No.: HT - Durable Sludge Transfer Screw Pump

Brand: HUTAO

Productivity: 2000L/Hour

Warranty: 1 year

Pressure: High Pressure

| Selling Units | : | Set/Sets |

| Package Type | : | Wooden box |

| Picture Example | : |

|

| Download | : |

|

The file is encrypted. Please fill in the following information to continue accessing it

Durable Sludge Transfer Screw Pump

Screw Pump Introduction

Screw-type Pump Advantages

1.High Efficiency: Double screw Pumps are highly efficient, with low energy consumption and minimal losses due to friction. This makes them an ideal choice for applications where energy efficiency is a concern.

2.Consistent Flow: Double screw pumps provide a consistent flow rate, even when handling fluids with varying viscosity. This is because the screw geometry creates a continuous flow path, which eliminates pulsation and ensures a steady stream of fluid.

3.High Pressure Capability: Double Screw Pump is capable of generating high discharge pressures, making them ideal for applications where high head is required.

4.Minimal Maintenance: Double screw pumps have a simple, robust design that requires minimal maintenance. They have fewer moving parts than other pump types, reducing the risk of failure and extending the pump's service life.

5.Versatility: Double screw pumps can handle a wide range of fluid viscosities, from thin liquids to highly viscous materials. They can also handle abrasive and corrosive fluids, making them a versatile choice for a range of industrial applications.

6.Low Noise and Vibration: Double screw pumps operate quietly and with minimal vibration, reducing the risk of damage to surrounding equipment and creating a more comfortable working environment.

Single Screw Pump Structure Details

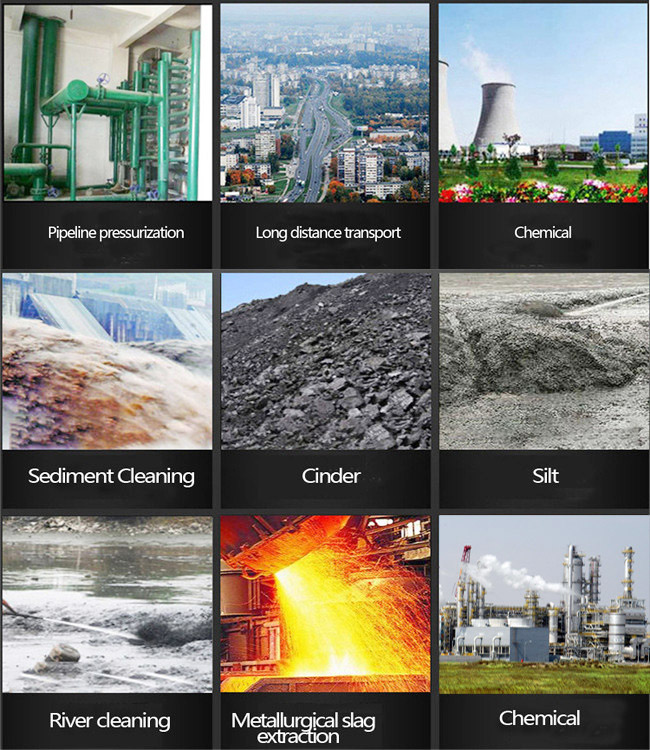

Progressing Cavity Pump Application

1. Environmental protection: transportation of industrial sewage, domestic sewage and muddy water containing solid particles and short fibers. It is especially suitable for oil-water Separator, plate and frame filter and other equipment.

2. Shipbuilding Industry: ship bottom cleaning, transmission of oil-water, oil residue, oily water and other media.

3. Petroleum Industry: transporting crude oil. In recent years, it has been especially successful in pumping the mixture of crude oil and water, which is thousands of materials deep underground, and the mixture of coal and water in the coal field, thus greatly reducing the cost of mechanical oil extraction and coal field gas. When the oil field reaches the late stage, the screw pump is used to inject polymer into the formation to increase the oil recovery.

4. Medicine, daily Chemical: transportation of various viscous pastes, emulsions, ointments, cosmetics, etc.

5. Food canning industry: transportation of various viscous starch, edible oil, honey, sugar sauce, fruit pulp, cream, surimi, minced meat and their leftovers.

6. Brewing industry: all kinds of fermented mucking liquid, distiller's grains, grain product residues, all kinds of sauces, pulps and mucus containing massive solid substances.

7. construction industry: spraying and conveying of Cement mortar, lime slurry, coating and other pastes.

8. Mining industry: underground and sewage slurry containing solid particles in the mine are discharged to the ground.

9. Chemical industry: various suspensions, greases, colloidal slurries and adhesives.

10. Printing and paper industry: transportation of high viscosity inks, PVC polymer plastic pastes for wallpapers, pulp and short fiber pastes of various concentrations.

Slurry Screw Pump Specification

| Product Name | Screw pump |

| Voltage | 220V / 380V |

| Flow | 10~90m3/h |

| Suction Diameter | 3~6 inch |

| Head | 1~ 99m |

| Power | up to 120 kw |

| Material | Cast iron/Stainless Steel(SS304/SS316L/SS904) |

| Warranty | 1 year |

Huatao Pumps Application

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.