Nano-Aerogel Composite Coating for Thermal Insulation

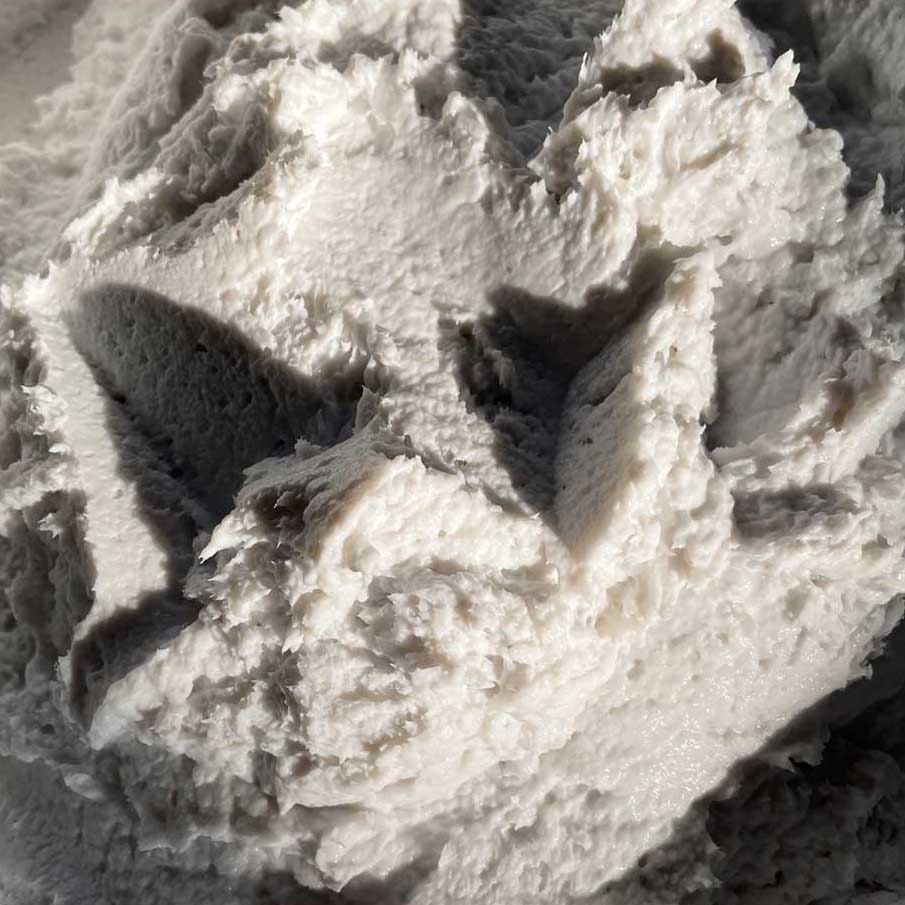

Aerogel Coating Description

Nano-aerogel composite thermal insulation Coating is a new type of aerogel insulation material. It is a viscous slurry made of a variety of inorganic fibers, nano-silica aerogel fillers, and other materials, using water as a dispersion medium, adding a special binder, and fiber dissolution and stirring. It can be directly coated on the substrate of the protected metal or other materials by spraying or daubing, etc., Forming a protective layer with high-efficiency heat preservation by baking and curing at room temperature or low temperature. The product has the characteristics of low thermal conductivity, high bonding strength, short drying time, low shrinkage, and is not easy to crack after drying. It's the best choice for equipment, storage tanks, special shapes, and complex working conditions.

Aerogel Coating Specifications

| Item | Unit | Technical Data |

| Temperature Max. | ºC | 500 |

| Slurry Density | kg/m³ | 1050 |

| pH | | 8.5 |

| Dry density | kg/m³ | 260 |

| Volume shrinkage | % | ≤5 |

| Tensile Strength (After Dry) | kPa | 476 |

| Bond strength | kPa | 86 |

| Thermal Conductivity(25ºC) | W/(m·K) | 0.05 |

| Hydrophobic rate | % | 97.6 |

| Non-combustibility | | A1 Grade |

| 10mm thickness/m2 material | kg | 11 |

| Bucket loading quantity | kg | 20 |

Aerogel Coating Advantages

1. Superior Aerogel Insulation Performance

2~5 times better than traditional insulation products with longer service life.

2. Reduced Insulation Thickness

For the same insulation performance, just take a portion of the thickness of traditional material.

3. Hydrophobicity and Fire-proof

Repel water from penetrating into pipes, and equipment, A1 rating of fire-proof.

4. Easy Handling

Lightweight, easily cut and sewn to fit different shapes of pipes and equipment, Less labor for installation.

5. Transportation Costs Savings

Lower packing volume and lower weight can greatly cut down logistics costs.