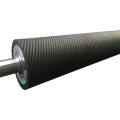

Crowned Roll for Toilet Paper Machine

Crowned Roll Description

Crowned roller is a rubber roller whose diameter in the middle section is slightly larger than the diameter of the two end sections. From the section through the axis line, it is the roller with high middle and low ends of the rubber layer. Intuitively, the shape of the Crowned roll is an olive shape. From the point of view of material mechanics, the distributed load within a certain width must lead to a certain degree of bending deformation of the roll. This deformation inevitably affects the uniformity and stability of the pressure between the roll and the Steel Roll or base material. The main purpose of using Crowned roller is to make up for the bending deformation during the rotation of the roller under pressure, so that the roller can have uniform contact pressure (line pressure or pressure consistency) with the steel roller or substrate in the whole working area, thus achieving balanced and stable transfer coating or compounding.

Crowned Roll key indicator

The mid-height value is the key indicator to measure the characteristics of Crowned rolls, which is the difference between the radius of the middle area of a Rubber Roll and the radius of the area at both ends, i.e. the difference between the maximum and minimum radius of the rubber roll. Since the bus line of the Crowned roller is an outwardly convex curve, it is sometimes called the mid-height curve or mid-height line.

What factors depend on the medium and high values

(1)Roller length to diameter ratio.

(2)Maximum working pressure.

(3)Maximum working speed of rubber roller

(4)The material of rubber roller.

(5)The actual working width of the roller.

Crowned Roll Specification

| Product name | Crowned Roll |

| Working Temperature | up to 300 |

| Specification | Make to order |

| Diameter | 590-1880 |