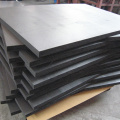

Graphite Insulation Felt for Vacuum Furnance

Graphite Insulation Felt Description

Viscose graphite felt is made of viscose fiber as the base material, which is formed after high-temperature treatment of pre-oxidation, carbonization, and graphitization. It has good shape retention, self-supporting, small specific gravity, no short fiber shedding, high surface finish, low thermal conductivity, high-temperature resistance, good thermal shock resistance (long-term use without cracking, no deformation), long service life, is easy to install and disassemble, and the operating temperature can reach 3000 ℃. It is an ideal new Thermal Insulation Material for high-temperature vacuum equipment and high-temperature equipment in a non-oxidizing atmosphere.

Graphite Insulation Felt Specifications

| Product Name | Graphite Insulation Felt |

| Base Material | Viscose fiber |

| Density | 0.13~0.15g/cm3

|

| Carbon Content | ≥99%

|

| Thermal Conductivity | 0.08-0.14w/m.k

|

| Thickness | 5, 8, 10mm |

Graphite Insulation Felt Features 1. Excellent thermal performance over a wide operating temperature range.

2. High stability, low shrinkage.

3. Flexible and easy to operate.

4. Low density and thermal mass.

5. More efficient heating and cooling.

6. Low thermal conductivity.

7. Uniformity throughout the material.

8. Available in different lengths, widths, and thicknesses.

9. Easy to cut to meet specific size requirements.

10. Halogen purification is possible to reduce impurity levels to the ppm range.

Huatao Group could also supply other thermal insulation materials as follows:

1. Aerogel Insulation Blanket

2. Aerogel Insulation Board

3. Aerogel Insulation Film

4. Aerogel Coating

5. Aerogel Powder

6. Aerogel Particle

7. Vacuum Insulation Panel