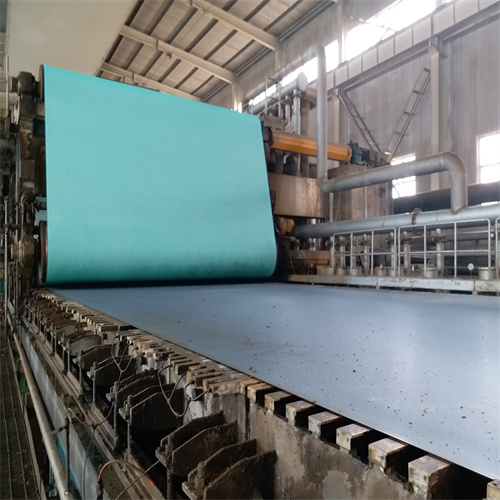

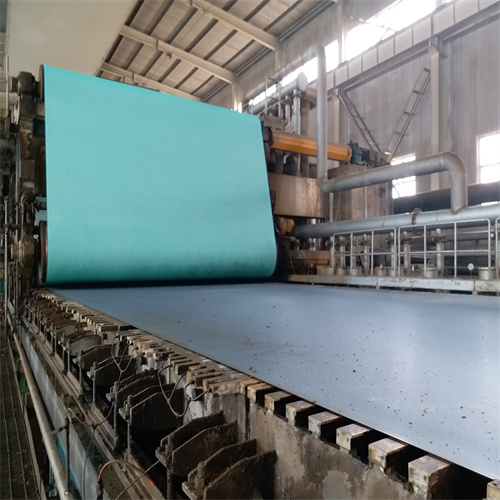

Triple Layer Polyester SSB Forming Fabric for Paper Making Machine

About SSB Triple Layer Forming Fabric

Multi-shed three-layer Polyester forming fabrics suitable for making quality printing paper, tissue paper and cigarette paper etc.

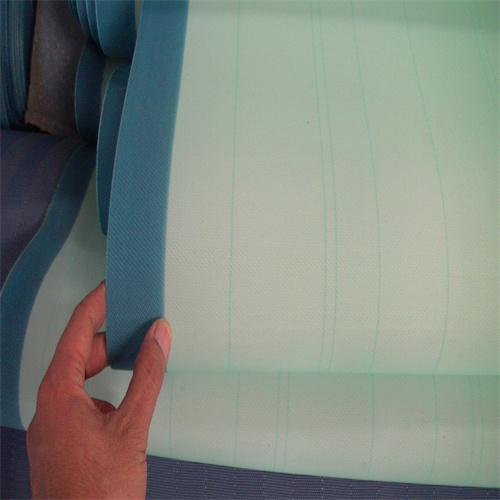

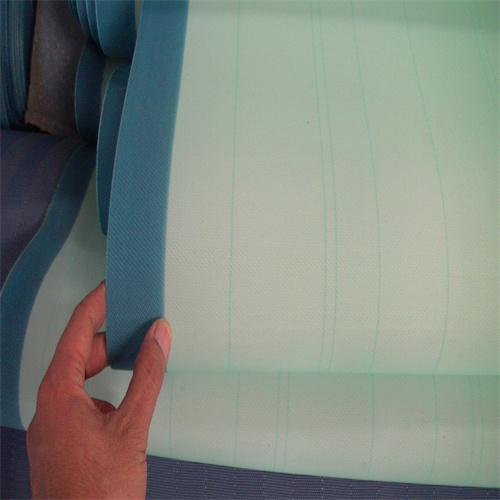

SSB forming fabric woven using 24 harness technology, which allows 6 shaft machine side construction to promote improved life potential. Available with 2 or 3 shaft paper side construction and 3:2, 2:1 or 1:1 weft ratio. Excellent raw material is used to further improve life potential and reduce power consumption. Huatao's SSB forming fabric family has options in 56, 36, 42, 60 styles depending upon application or paper grade. The 56 design benefits from high modules machine direction yarns which promote high FSI without compromise to dimensional stability. Huatao's SSB triple layer forming fabric should be available to all former types.

SSB Triple Layer Forming Fabric style 36 is a medium coarse weft-bound forming fabric that is used on board and packaging paper machines. The fabric design especially features excellent formation, drainage and fabric stability.

Style 36 is an SSB triple layer forming fabric that is especially suitable for demanding light-weight board and packaging applications which have to meet high paper quality requirements. Due to the unique warp concept of the style, a fine paper side can be combined with an extremely stable machine side. This unique fabric design leads to optimized fabric surfaces for improved paper quality.

SSB Forming Fabric Advantage

High Open Areas for Fast Dewatering Performance,

Cleaner Headbox Operation,

reduce wear on dewatering element and Improved Sheet Formation,

Better Mechanical Retention Leading to Higher FSI,

High Wear Volumes Ensuring Excellent Fabric Life,

Outstanding Fabric Stability, Good Guiding Stability on Demanding Applications.

SSB Triple Layer Technical Parameters (The forming fabric can be customized)

| FABRIC CODE | WARP DENSITY | WEFT DENSITY | WARP DIAMETER | WEFT DIAMETER | AIR PERMEABILITY | FSI | DI |

| HT6020 | 69.5~70.5 | 79.5~80.5 | 0.13, 0.20 | 0.13 0.13, 0.27 0.27 | 250CFM | 195 | 25.4 |

| HT5220-1 | 59.5~60.5 | 62.5~63.5 | 0.13, 0.20 | 0.13 0.13, 0.25 0.25 | 540CFM | 157 | 43.2 |

| HT5220-2 | 59.5~60.5 | 63.5~64.5 | 0.13, 0.20 | 0.13 0.13, 0.30 0.30 | 445CFM | 159 | 36.2 |

| HT5224 | 51.5~52.5 | 57.5~58.5 | 0.17, 0.25 | 0.17 0.17, 0.40 0.40 | 250CFM | 142 | 18.4 |

| HT4224 | 41.5~42.5 | 43.5~44.5 | 0.22, 0.30 | 0.22 0.22, 0.45 0.45 | 350CFM | 110 | 19.6

|

Related Products: Press Felt, Dryer Screen

Apart from the Paper Machine Clothing (Forming Fabric, Press Felt , Dryer Screen), Huatao provides a host of specialty and performance

Paper Machine Spare Parts : Headbox, Dewatering Element, Paper Machine Rolls, Cylinder Mould, Doctor Blade and its holder, etc. More details please kindly view our webiste.

Product photos

FAQ

Q: How to confirm the type?

A: There are many methods for us to confirm the type:

1). tell us the specifications data.

2). our engineers will give you the best suggestion and design the most suitable forming fabric according to your paper machine details.

3). send us the photos with size

4). send us a small piece sample.

Q: Waht is the payment terms?

A: We prefer T/T, but for some countries, we will also accept L/C.

Q: When will delivery the goods?

A: Usally, we will deliver the goods within 15 working days. And if the quantity is big, it will take about 20-30 working days.

Q: How long will the fabric be used?

A: The time is different differ the usage and factory. But we can confirm and make sure that our product can be used longer than any other one in China.

Q: Is the package strong enough for the long transportation?

A: Of course it is.

By sea, we will pack every piece into wooden/ polywood box.

By air, we will pack it by strong water-proof bag.