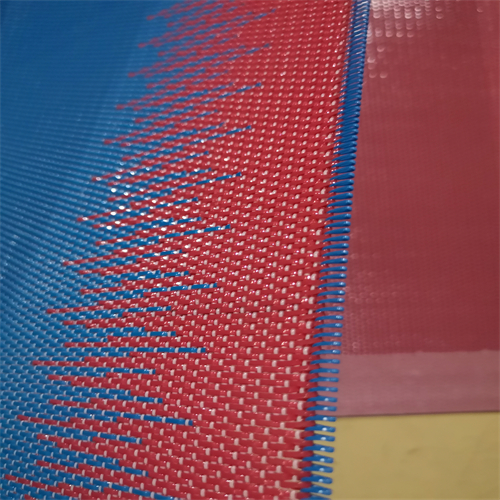

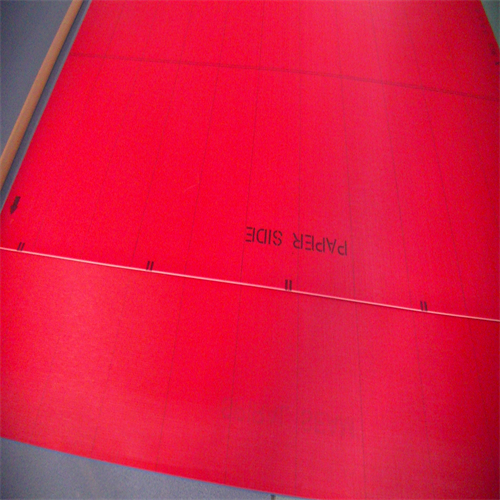

Paper Machine Polyster Woven Dryer Fabric

Huatao has launched new woven dryer screen, which is a unique two-tier flat warp weave screen with controlled permeability, recommended for Unirun positions and high speed machines. The higher surface contact area helps to increase the heat transfer with better sheet support thus lowering the energy consumption and has a potential for, higher life. Polyester Woven Dryer Fabric, avariety of free shrinking,breaking,elongation,tolerance is available.Widely used in producing of paper,also in filteration and sieving in various fields.

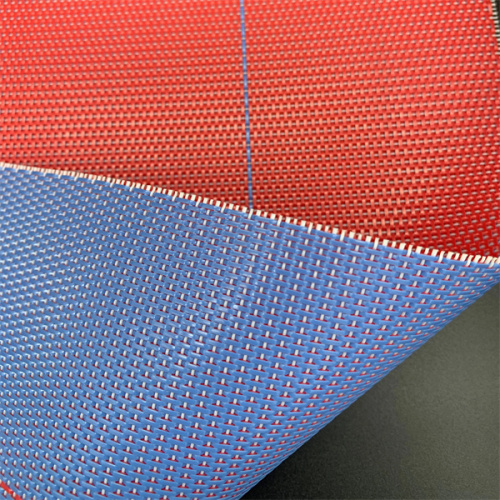

According to the weaving, polyester dryer fabric can be divided into 3-shed, 4-shed. According to the category, polyester dryer fabric can be divided into one and a half layers, double layer, and rectangular wire fabric.

3-shed one-layer and a-half polyester dryer fabric are suitable for drying papers below 70g.

4-shed double-layer polyester dryer fabric is suitable for drying papers above 70g.

Rectangular wire polyester dryer fabric is suitable for the fore several heating boxes of the drying zone, quality papers can use all.

24504/22504/20654/4106 for multi-cylinder paper machine, due to higher permeability, generally used in the latter part of the paper machine dryer, the production of paper of more than 70 grams.

4106-2/18688/16904 generally used for multi-cylinder paper machines, the first three groups of paper drying, high-grade paper.

Dryer Fabric Application

1. Filtering and separating in the colliery, food, salt and mine industry

2. Pulp making, soleplate pulp packing and cardboard pulp

3. Fiberboard plants, medicine, printing, drying industry as conveyor belt pharmacy, environment protection

4. Process hides, shoe-making, clothing, ceramics etc as a conveyor belt

5. Foodstuffs processing

Dryer Fabric Package

According to the needs of customers and different modes of transportation, we adopt different packaging methods.The packaging method also depends on your needs.

1. Polyethylene bags are commonly used in air transportation, so our customers can reduce the freight.

2. Packing in wooden cases is the best choice for shipping, which can effectively avoid damage to goods.

3. Some customers also ask us to pack in cartons.

Dryer Screen Quality control

1. Fabric surface checking

2. Flatness testing

3. Wire tensile strength testing

4. Heat-setting by computer controlling

Related Products: Forming Fabric, Press Felt

Apart from the Paper Machine Clothing (Forming Fabric, Press Felt, Dryer Screen), Huatao provides a host of specialty and performance paper machine spare parts: headbox, dewatering element, Paper Machine Rolls, cylinder mould, doctor blade and its holder, etc. More details please kindly view our webiste.

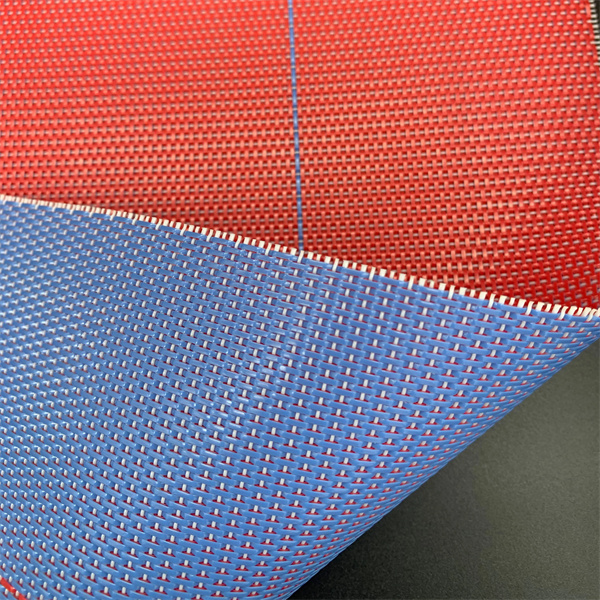

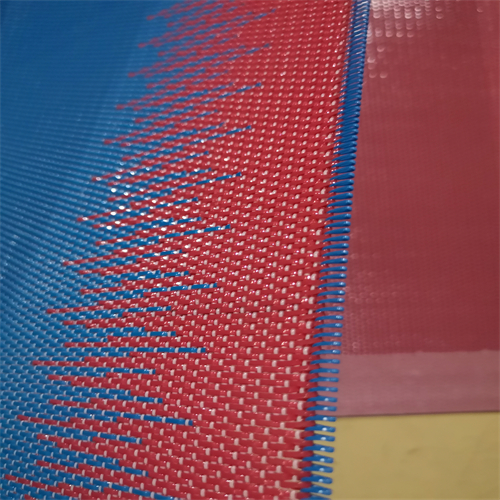

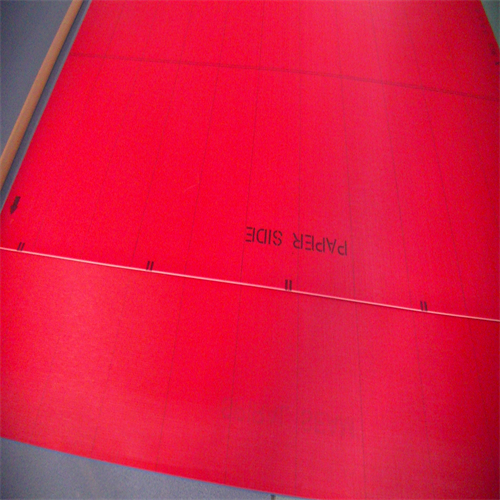

Product Photos of Polyester Dryer Screen