Plastic Powder Sorting Rotating Vibrating Sieve Machine

$1200≥1Set/Sets

| Payment Type: | L/C,T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,CPT,Express Delivery |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shanghai,Beijing,Tianjin |

$1200≥1Set/Sets

| Payment Type: | L/C,T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,CPT,Express Delivery |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shanghai,Beijing,Tianjin |

Brand: Huatao

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Core Component Warranty Period: 1 Year

Types Of: Circular

Use: Chemicals

Place Of Origin: China

Warranty Period: 1 Year

| Selling Units | : | Set/Sets |

| Package Type | : | wooden box |

| Picture Example | : |

|

The file is encrypted. Please fill in the following information to continue accessing it

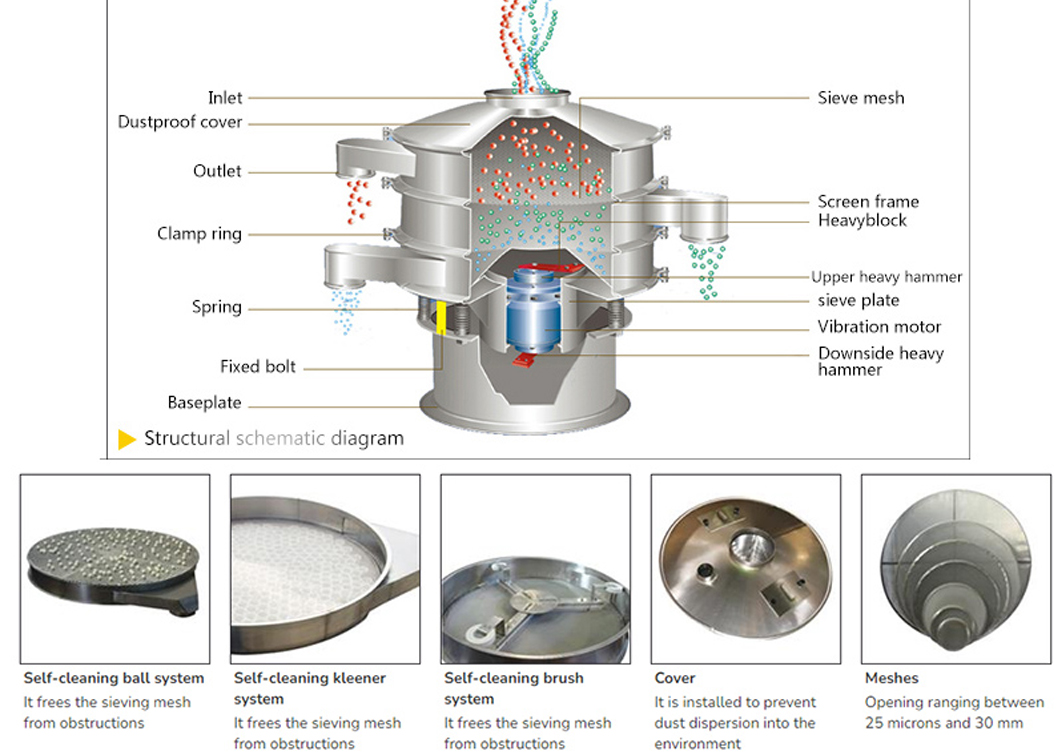

Plastic Powder Separator Sift Rotating Vibrating Sieve Machine

Function of Ultrasonic Vibrating Screen

1. Ultrafine powder screening: Really solve the screening problems of the characteristics material of strong adsorption, adhesion, sticky, high static, high density, ultrafine powder, etc.

2. Solve the network blockage: convert 220V, 50Hz electric energy into 38KHz high frequency electric energy, input the ultrasonic transducer, and turn it into 38KHz mechanical vibration, so as to achieve the purpose of screening and cleaning the network, making it easy to screen fine powder Increasing the penetration rate and reducing the clogging of the screen.

3. Reduced costs: eliminates mesh damage normally associated with mechanical cleaning devices, increasing mesh life

Benefits of Ultrasonic Vibrating Screen

Suitable for Ultra-fine Powder

Solved the problem of the sieving of strong adsorption, free huddle, strong stickiness, high static, high density, ultrafine powder, etc.

Not Clog the Mesh

The vibration frequency of the ultrasonic vibrating screen is 360,000 times/minute, which effectively prevents the screen from clogging, and the materials that are difficult to screen hardly block the mesh.

Improve Efficiency

The accuracy of the sieve can be increased by more than 80% and the output is increased by 2-5 times.

Lower Cost

There is no need to add a screen cleaning device, except for the damage of the mesh usually associated with mechanical cleaning equipment, and increase the service life of the mesh.

Working Principle of Ultrasonic Vibrating Screen

Ultrasonic vibrating screen can input 220V, 50Hz or 110V, 60Hz electric energy into the ultrasonic transducer, and turn it into 36KHz mechanical vibration. Ultrasonic vibrating screen can input 220V, 50Hz or 110V, 60Hz electric energy into the ultrasonic transducer, and turn it into 36KHz mechanical vibration. The generated ultrasonic wave makes the screen mesh vibrate at a high frequency. The materials on the screen surface are superimposed with ultrasonic vibration while performing low-frequency rotational vibration, which can not only prevent mesh clogging, but also improve the output and product quality of the screening machine, making the ultrasonic vibrating screen easy to screen ultrafine powder.

Technical specification about the rotary vibration screen

| Model | Testing materials | Ordinary screening machine | UItrasonic vibrating screen | ||

| Mesh | Test results | Mesh | Test results | ||

| φ1000 | Silicon carbide | 500 | Unable to screening | 500 | 1500KG/H |

| Tungsten powder of cemented carbide | 600 | No fine powder was sifted out for 15 minutes | 600 | 30KG/H | |

| vitamin c powder | 400 | 1KG/H | 400 | 120-150KG/H | |

| φ500 | Pollen | 400 | No fine powder was sifted out for 15 minutes | 400 | Screen out 20% in 15 minutes.Fine and effective classification can be carried out in fine workmanship. |

| Nickel powder,Cobalt powder | 325 | Screen three times to meet the requirements | 400 | Screen once to meet the requirements | |

| φ450 | Ndfeb powder | 300 | 32.2% residual sieve in 30 minutes | 300 | 6.9%residual sieve in 30 minutes |

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.