Flip Flop Vibrating Screen

$5000-50000 /Set/Sets

| Payment Type: | L/C,T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,CIP,FCA |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land,Air |

| Port: | QINGDAO,TIANJIN,SHANGHAI |

$5000-50000 /Set/Sets

| Payment Type: | L/C,T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,CIP,FCA |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land,Air |

| Port: | QINGDAO,TIANJIN,SHANGHAI |

Model No.: HT - Flip Flop Vibrating Screen

Brand: HUATAO

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Core Component Warranty Period: 1 Year

Core Components: Motor, Plc, Engine, Bearing, Gearbox, Pressure Vessel, Gear, Pump

Status: New

Types Of: Linear

Use: Ore

Place Of Origin: China

Warranty Period: 1 Year

Applicable Industry: Energy &Amp; Mining, Manufacturing Plant

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): Canada, Viet Nam, India, Morocco, Algeria, Ukraine, Kazakhstan, Pakistan, Australia, Colombia, Germany, Egypt, Turkey, Philippines, Mexico, Kenya, Sri Lanka, Kyrgyzstan, Nigeria, Romania, Argentina, Russia, Brazil, United Kingdom, United States, Peru, Spain, South Korea, Bangladesh, Uzbekistan, Tajikistan, South Africa, Chile, Thailand, Saudi Arabia, Italy, Japan, Uae, Malaysia, Indonesia, France

Usage: Screening Machine

Screen Width: 1000mm-4300m

Length: 4m-12m

Screen Inclination: 5-30 degrees

Type:: Single-layer, double-layer, triple-layer etc

Brand: HUATAO

| Selling Units | : | Set/Sets |

| Package Type | : | Exported standard package |

| Picture Example | : |

|

The file is encrypted. Please fill in the following information to continue accessing it

Flip Flop Vibrating Screen

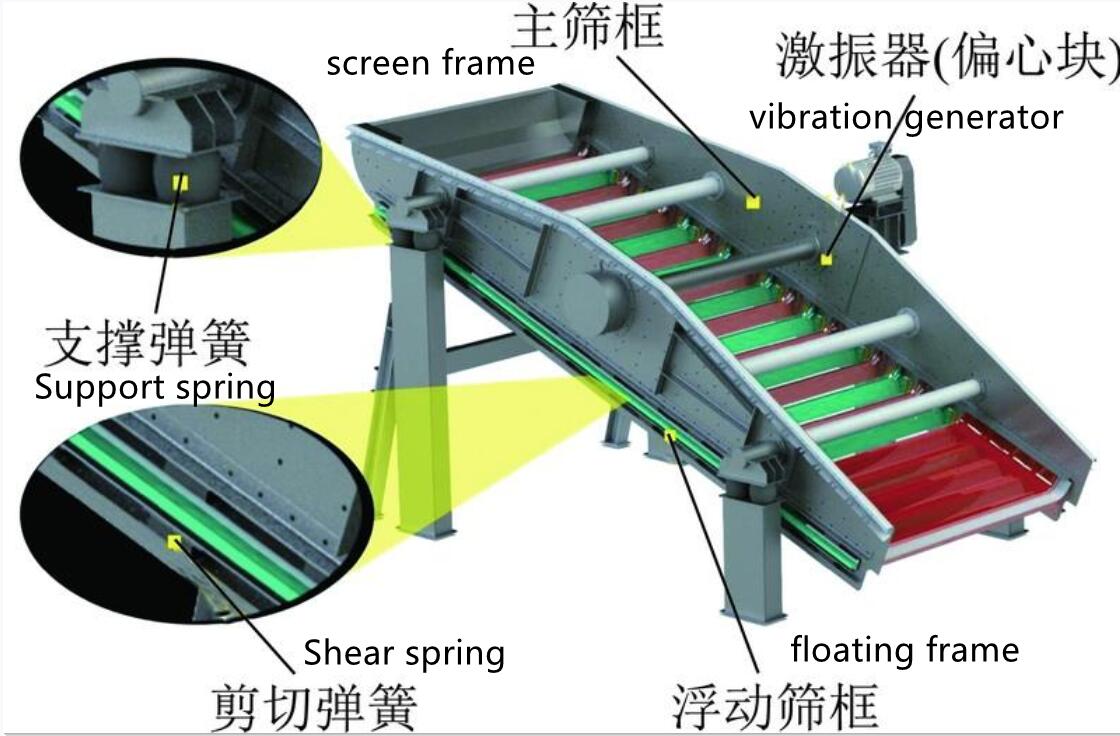

Description of Flip-Flop Vibrating Screen:

Flip-Flop Vibrating Screen is a screening machine specially designed to sort medium and fine-grained viscous and disperse materials that are difficult to screen, with a separation range of 1-30mm. The product is equipped with process structures such as accepting materials and sealing interfaces, which can be widely used in material classification in the process of mining, metallurgy, coal, building materials, hydropower, thermal power generation, city gas, municipal waste, sewage purification and other industries.

The Flip-Flop Vibrating Screen uses the principle of sub-resonance of two-mass body: the fixed screen frame of linear vibration and the excited floating screen frame form a resonance system, and the two produce relative motion. During this process, the elastic polyurethane screen surface continuously expands and contracts at a frequency of 800 times per minute, so as to obtain a high acceleration (50g), which effectively prevents the screen hole from clogging.

Advantages of Flip-Flop Vibrating Screen:

1. Since the screen surface can transmit the acceleration of 50G to the material by the relaxation movement, it can screen the difficult-to-screen materials, and the screen holes are not easy to be blocked.

2. The respective advantages of banana sieve and relaxation sieve are organically integrated. At the feeding end, the material speed is fast, the material layer is thin, a large amount of material is screened through, and the processing capacity is high. The inclination angle of the screen surface at the discharge end is low, and the material speed is slow, which can thoroughly screen the remaining under the screen and achieve a very high screening efficiency.

3. The box-type vibration exciter with linear motion has high reliability and simple maintenance.

4. The PU Panel of the relaxation screen is specially designed by Tongtai Machinery Company to withstand the vibration intensity of 50g and 800 times of varicose per minute. The sieve plate has a long service life and the sieve machine is located on a hollow rubber spring. Noise Small, and the rubber spring has a long life. The load on the screen and support structure is much smaller than that of a conventional slack screen (although the slack screen can generate a vibration intensity of 50g, which is much greater than the 5g of a traditional sieve).

5. The "U" shape of the side of the screening machine is designed to form a seal, the side plate is not worn, and it prevents the upper screen from entering the screen, and the screen plate is fixed with a wedge-shaped rubber strip without any bolts. The extension has few rotating parts, high operational reliability, less daily maintenance workload, high utilization rate, and adjustable amplitude of the floating screen frame.

Technical Parameters of Flip-Flop Vibrating Screen:

Screen width from 1000mm to 4300m

Lengths from 4m to 12m

Screen inclination from 5 degrees to 30 degrees

Single-layer, double-layer and triple-layer screen surface

The particle size range of dry sieving in coal application is 3mm-50mm

The processing capacity can be more than 1500 tons/hour (depending on the classification size)

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.