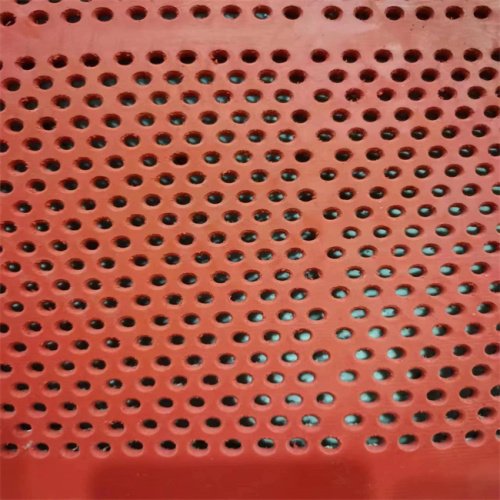

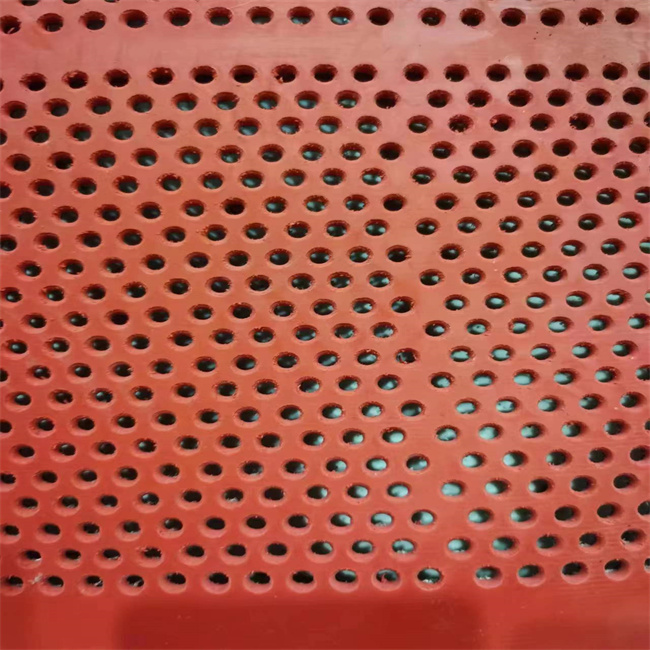

Rubber Self-Cleaning Screen Mat For Mining Screening

Description of Rubber Self-Cleaning Screen Mat

Rubber self-cleaning screen mat is vital in mining operations, where they're utilized in vibrating screens to sift and classify various ores, aggregates, and minerals. These mats withstand heavy loads and abrasive materials, efficiently preventing clogging or blinding of the screen apertures. By self-cleaning, they ensure continuous screening, enhancing the efficiency of mineral processing and improving overall productivity in the mining industry.

Parameters of Rubber Self-Cleaning Screen Mat

| Product Name | Rubber Self-Cleaning Screen Mat |

| Dimension | 1, 1.25 m width, the length could be customized |

| Aperture Size | 4-12 mm |

| Aperture Shape | Round, rectangle could be customized |

| Thickness | 6 mm, 8 mm could be customized |

| Installation Method | Hook installation |

| Material | Rubber imported from Thailand |

| Application | Mining, mineral processing, quarry and other aggregate screening. |

Features of Rubber Self-Cleaning Screen Mat 1. Prevention of Clogging: The design of these mats prevents material from getting stuck in the screen apertures, ensuring a continuous flow without interruptions caused by blockages.

2. Self-Cleaning Capability: Compared with Polyurethane Screen, The flexible nature allows them to vibrate or flex, dislodging and releasing trapped materials without requiring manual intervention or downtime for cleaning.

3. Enhanced Durability: Made from durable rubber compounds, these mats withstand abrasion, impact, and harsh conditions, prolonging their lifespan even in demanding industrial settings like mining or heavy material processing. The service life is 5-10 times that of metal mesh and more wear-resistant than PU Panel.

4. Improved Efficiency: By maintaining consistent screening performance, these mats increase operational efficiency, reducing downtime and maintenance intervals, and thereby boosting productivity.

5. Versatility: They are adaptable to various screening machines and applications, making them suitable for use in diverse industries such as mining, recycling, agriculture, and construction.

6. Cost-Effectiveness: Their long lifespan, reduced maintenance needs, and ability to prevent downtime contribute to cost savings over time compared to traditional screen mats.

7. Customization: They can be manufactured in various sizes, shapes, and configurations to suit specific screening requirements, providing tailored solutions for different industries and applications.