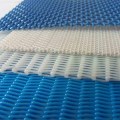

Polyester Spiral Press Filter Belt For Belt Press Machine

Polyester Spiral Press Filter Belt / Dryer Fabric Description

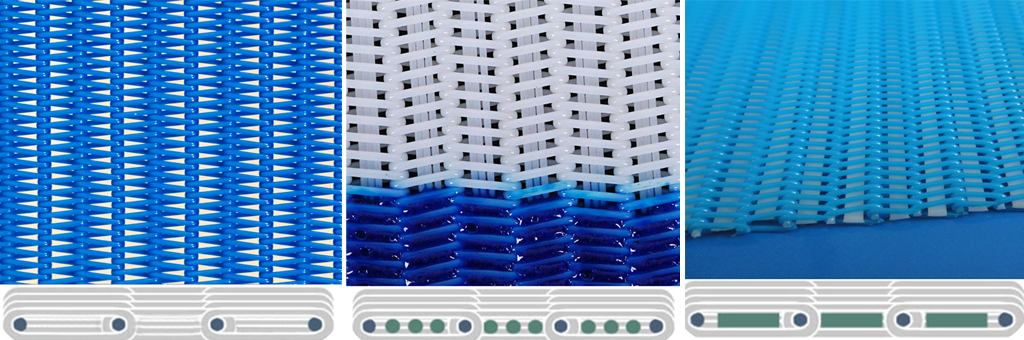

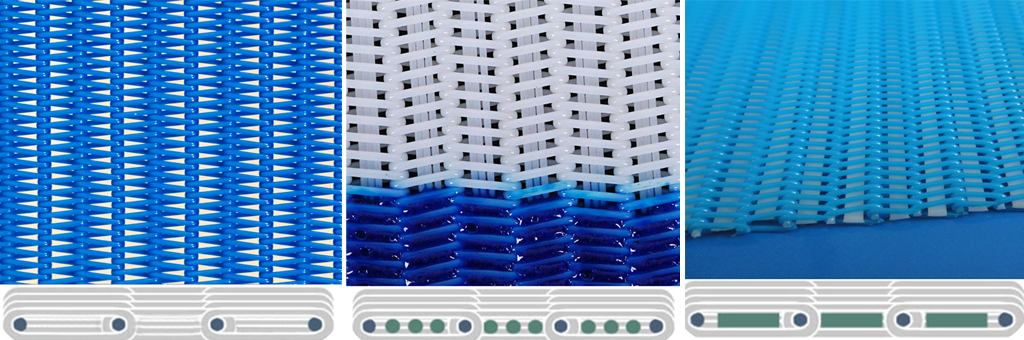

Polyester Spiral Press Filter Belts are made with spiral dryer fabrics with extra filler yarns inserted in the spiral loops to reduce air permeability and less material loss on the surface of the fabric. Polyester Spiral Press filter belts are usually made of abrasive-resistant polyester.

This kind of polyester spiral belt is made of polyester spiral dryer fabric which is filled with stuff to reduce the air permeation and to intensitive the opening, hence to reduce the material loss from the mesh opening. Polyester Spiral Link Dryer Fabric (Spiral Polyester mesh Belt)according to Finland standard with first-class monofilament. The characteristics of SLDF is stable running, not easy to wrinkled, high filtration rate and it can peel off easily from the filter cake.

Polyester spiral filter belt application

Polyester spiral press filter belt is suitable for high-pressure press-filter washer, horizontal belt washer, pulp-liquor separator and netting belt coal-washer. Polyester Spiral filter Belt/Filter cloth is widely used in all kinds of industries such as printing and dying, food, salt industry, pharmaceutical, environment protection, process hides, shoe-making, clothing, pottery and other conveyor belt est.

The spiral filter belt does not need extra joint seams like woven filter belts, because spiral coils at both ends of the spiral filter belt can be connected together. The spiral seam on the spiral filter belt is stronger and the lifetime of this connection is in some applications more durable that clipper seam AISI304/316, which is used for woven filter belts. Therefore spiral filter belt could be a solution for applications, where woven filter belts with a clipper seam prematurely fail.

Spiral Filter Belt edges are usually reinforced with glues that are both mechanically strong and very flexible. High-quality glue not only increases the mechanical strength of the belt edge but also firmly holds the weft in the fabric.

Polyester spiral press filter belt specification

| Model | warp thread diameter(mm) | weft thread diameter(mm) | filling wire | weight Kg/㎡ | thickness mm | CFM 127/Pa |

super loop

| 0.90

| 1.10

| 1.0*4

| 2.21

| 3.03

| 390

|

large loop

| 0.68

| 0.90

| 0.80*4

| 2.0

| 2.45

| 380

|

middle loop1

| 0.68

| 0.90

| 0.90*3

| 1.90

| 2.45

| 360

|

middle loop 2

| 0.68

| 0.90

| 0.80*3

| 1.85

| 2.45

| 484

|

middle loop 3

| 0.68

| 0.90

| flat yarn 2.1*0.8

| 1.80

| 2.45

| 563

|

middle loop 4

| 0.68

| 0.90

| flat yarn 2.4*0.85

| 1.85

| 2.45

| 500

|

small loop

| 0.50

| 0.80

| 0.60*3

| 1.5

| 1.87

| 280

|

Polyester Spiral Belt Description

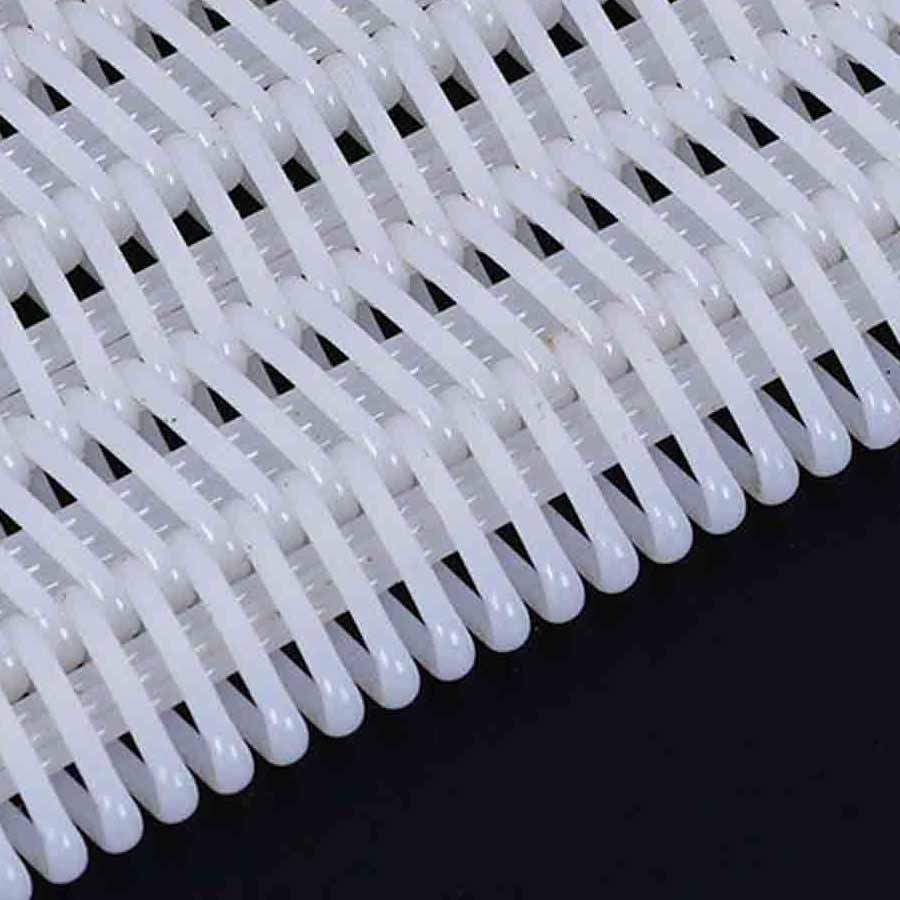

Spiral filter belt, spiral mesh dryer belts have a specially designed spiral structure. The spiral meshes are produced from flat ribbon spirals, which are connected to a straight round rod. Due to the special structure of the polyester spiral mesh belt with continuous and seamless screen spiral, it is very suitable for applications with high mechanical load and unmeet the seam.

Spiral mesh belt application

The characteristics of SLDF are stable running, not easy to wrinkle, high filtration rate and it can peel off easily from the filter cake. Polyester Spiral Belts are mainly used on paper

making, printing and dyeing, food, pharmaceutical, ceramics and sold & liquid separation industry, mine, metallurgy, and other fields.

Polyester Spiral Filter Belt Advantages:

Large air permeability with a long lifetime. Flat surface and Good Strength.

High-temperature resistance, abrasion resistance, and aging resistance.

Perfect seamless structure with good excellent elongation resistance Great resistance to chemicals, such as acids and organic solvents.

Polyester Spiral Filter Belt Specification

| Model | warp thread diameter (mm) | weft thread diameter (mm) | The specification of single | weight (kg/m2) | thickness (mm) | CFM (127 / Pa) |

| Large loop | 0.9 | 1.1 | LW 4.0×8.0mm | 1.7 | 3 | 900cfm - 1250cfm |

| Medium loop | 0.7 | 0.9 | LW 3.8×6.8mm | 1.4 | 2.5 | 900cfm - 1250cfm |

| Small loop | 0.5 | 0.7 | LW 3.2×5.2mm | 1.1 | 1.9 | 900cfm - 1250cfm |