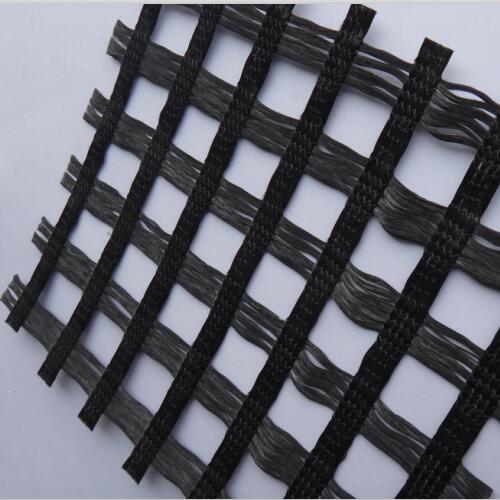

High Strength Warp Knitted Polyester PET Woven Geogrid

Polyester Geogrids Description Reinforcement Geogrid is a new type of enhanced quality subgrade

Geotextile substrate, the use of high-strength polyester fiber or polypropylene fiber as raw material, weaving through the warp direction, with a special coating treatment from dipping. We can supply the Biaxial and Uniaxial geogrid and we can also suplly geogrid covered with Geofabrics-Nonwoven Geotextile.

PET Geogrids Specification 1. Mesh Size: conventional geogrid mesh size of 12.7mm and 25.4mm.

2. Width : 2m, 4m and 6m. Or as request.

3. Customized request: geogrid strength, width and mesh size can be customized according to your request.

4. Loading: 20ft container, 40ft high container

PET Woven Geogrids Performance has a very high tensile strength

low elongation

corrosion resistance, aging

the base material has a strong bite force

light weight, there is drainage

Geogrids Application Various road soft soil subgrade reinforcement 1, roads, railways, roads and other municipal enhanced, can effectively improve the strength of subgrade, delaying reflection cracks in the road.

Water Project dams, channel reinforced, isolation, reinforcement of soft soil foundation, enhance its defense capabilities, improve the bearing capacity and stability.

For embankment reinforcement, retaining wall reinforcement, enhance the overall strength.

PET Geogrid Technical Specification

Huatao supply the geosynthetic materials products include: Non woven geotextile, Nonwoven geotextile, Woven geotextile, PP woven fabric, Weedmat, PET woven geotextile, High strength geotextile fabric, Geomembranes, HDPE Geomembrane, LDPE geomembrane, PVC geomembrane, Geogrids, Biaxial geogrid, Uniaxial geogrid, Polyester geogrid, Fiberglass geogrid, Geocell, Geoweb, HDPE Geocell, GCL, Geosynthetic Clay Liner, Geonet, Geomat, HDPE Geonet, Drainage Geonet, Geobag, Geotube, And so on.

PET Geogrid Technical Specification

| Properties | Test Method | Unit | PET30/20 | PET55/20 | PET60/30 | PET70/30 | PET80/30 | PET100/30 | PET120/30 |

| Ultimate tensile strength | MD | ASTM D 6637 | ≥ KN/M | 30 | 55 | 60 | 70 | 80 | 100 | 120 |

| CD | 20 | 20 | 30 | 30 | 30 | 30 | 30 |

| Elongation at maximum load | MD | ASTM D 6637 | ≤ % | 13 | 13 | 13 | 13 | 13 | 13 | 13 |

| CD | 13 | 13 | 13 | 13 | 13 | 13 | 13 |

| Approximate mesh size | - | MM | 12.7x12.7 25.4x25.4 50x50 |

| Roll Width | - | M | 3.95 or 5.95 | 3.95 or 5.95 | 3.95 or 5.95 | 3.95 or 5.95 | 3.95 or 5.95 | 3.95 or 5.95 | 3.95 or 5.95 |

| Properties | Test Method | Unit | PET150/30 | PET200/30 | PET260/30 | PET300/30 | PET350/30 | PET400/50 | PET500/50 |

| Ultimate tensile strength | MD | ASTM D 6637 | ≥ KN/M | 150 | 200 | 260 | 300 | 350 | 400 | 500 |

| CD | 30 | 30 | 30 | 30 | 30 | 50 | 50 |

| Elongation at maximum load | MD | ASTM D 6637 | ≤ % | 13 | 13 | 13 | 13 | 13 | 13 | 13 |

| CD | 13 | 13 | 13 | 13 | 13 | 13 | 13 |

| Approximate mesh size | - | MM | 25x25 40x40 50x50 |

| Roll Width | - | M | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 |

| Properties | Test Method | Unit | PET600/50 | PET700/50 | PET800/50 | PET900/50 | PET1000/50 | - | - |

| Ultimate tensile strength | MD | ASTM D 6637 | ≥ KN/M | 600 | 700 | 800 | 900 | 1000 | - | - |

| CD | | 50 | 50 | 50 | 50 | - | - |

| Elongation at maximum load | MD | ASTM D 6637 | ≤ % | 13 | 13 | 13 | 13 | 13 | - | - |

| CD | | 13 | 13 | 13 | 13 | - | - |

| Approximate mesh size | - | MM | 25x25 40x40 50x50 | |

| Roll Width | - | M | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 | - | - |