Eccentric Rotary Screw Pump

$1000≥1Set/Sets

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,CPT,CIP,Express Delivery |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shanghai , Qingdao ,Tianjin |

$1000≥1Set/Sets

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,CPT,CIP,Express Delivery |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shanghai , Qingdao ,Tianjin |

Model No.: HT - Eccentric Rotary Screw Pump

Brand: HUTAO

Flow: 10~90m3/h

Productivity: 2000L/Hour

| Selling Units | : | Set/Sets |

| Package Type | : | Wooden box |

| Picture Example | : |

|

| Download | : |

|

The file is encrypted. Please fill in the following information to continue accessing it

Eccentric Rotary Screw Pump

Screw Pump Introduction

Progressing Cavity Pumps can be used in any area of industry (Environmental technology, Foods, Chemicals and Oil), where a great variety of different substances must be pumped or very precisely dosed. From low viscosity media to products barely capable of flowing with or without solid content, shear-sensitive, sticky or abrasive. Suchas wastewater, activated sludge, plaster and cement mortar, acids, lime water, emulsion paints, soaps, adhesives, etc. with the S T D- SN, especially suitable for oil and water separators, plate frame filter press and other equipment.

Contact us, we can also help you according to your request to develop the exclusive best solution.

Screw-type Pump Advantages

Excellent construction system of screw Eccentric Rotary screw pump

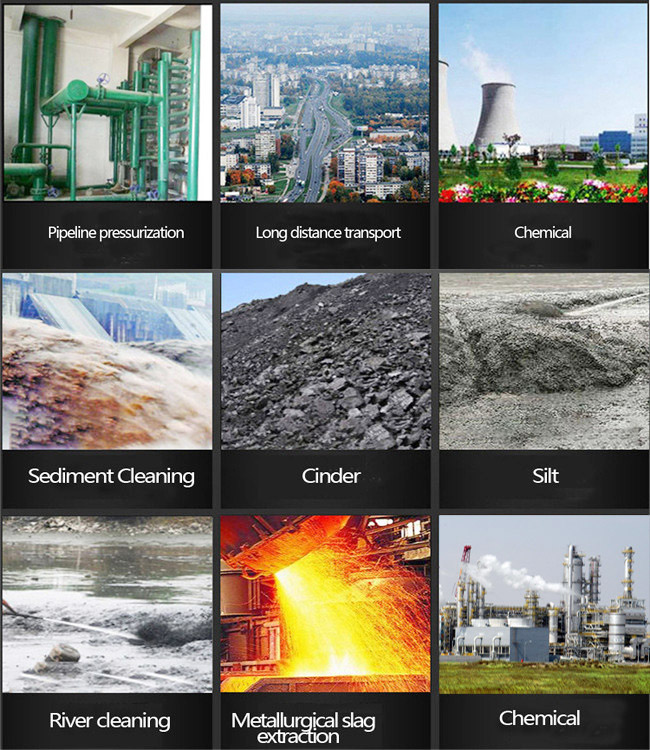

Progressing Cavity Pump Application

Slurry Screw Pump Specification

| Product Name | Screw pump |

| Voltage | 220V / 380V |

| Flow | 10~90m3/h |

| Suction Diameter | 3~6 inch |

| Head | 1~ 99m |

| Power | up to 120 kw |

| Material | Cast iron/Stainless Steel(SS304/SS316L/SS904) |

| Warranty | 1 year |

Huatao Pumps Application

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.