Marine Vertical Three Screw Pump

$1200≥1Set/Sets

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,CPT,CIP,DAF |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shanghai ,Qingdao ,Tianjin |

$1200≥1Set/Sets

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,CPT,CIP,DAF |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shanghai ,Qingdao ,Tianjin |

Model No.: HT - Marine Vertical Three Screw Pump

Brand: HUTAO

Warranty: 1 year

Type Of Connection: Flange

Working Temperature: -30 Degree Centigrade to 220 Degree Centigrade

| Selling Units | : | Set/Sets |

| Package Type | : | Wooden box |

| Picture Example | : |

|

| Download | : |

|

The file is encrypted. Please fill in the following information to continue accessing it

Marine Vertical Three Screw Pump

Screw Pump Introduction

The three-screw pump is formed by the pump body and the screw. When the driving screw rotates, it drives the driven screw that engages with it to rotate together. The volume of the screw meshing space at one end of the suction chamber gradually increases and the pressure decreases. Generally, a mechanical seal is used, and the pump is driven by a motor through a claw coupling. Viewed from the extended end of the main shaft to the pump, it rotates clockwise. It is used in all fields widely to feed kinds of medium, running at a constant pressure continuously, without and damage when feeding medium, and change the gauging through adjusting rotation speed.

Screw-type Pump Advantages

Single Screw Pump Operation Principle

A screw pump is a type of positive displacement pump that uses one or more screws to move fluids through a system. The screw(s) rotate in a cylindrical chamber, and as they turn, they trap fluid and move it from the inlet to the outlet of the pump. Screw Pumps are known for their ability to handle a wide range of fluids, including high viscosity liquids, slurries, and liquids with solid particles. They can also operate at high pressures and with low pulsation, making them a popular choice for many industrial applications.

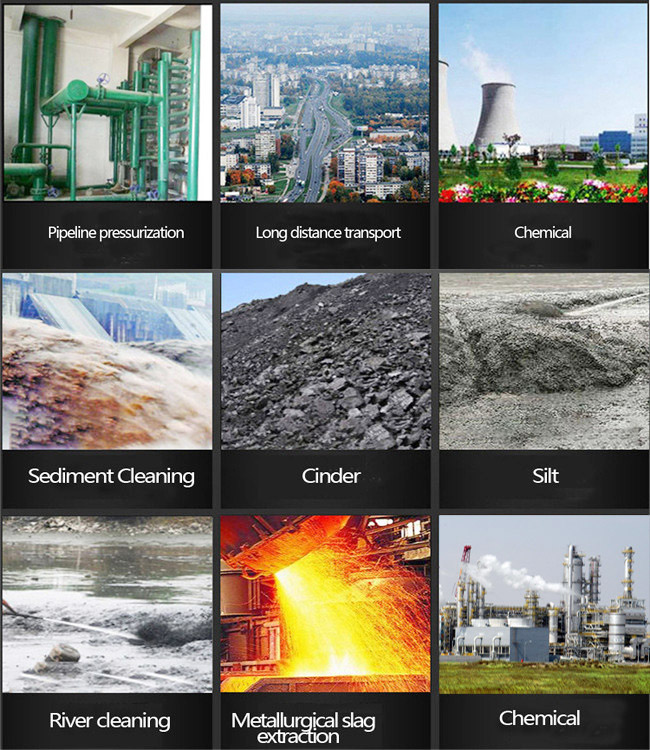

Progressing Cavity Pump Application

Products can transport all kinds of media with lubricity and no solid particles, mainly conveying lubricant (oil) media, such as lubricating oil, mechanical oil, hydraulic oil, gear oil, turbine oil, etc. While meeting the requirements of the original three-screw pump, it can also meet the conditions of high-rotation and low-viscosity conditions, and is suitable for machinery, petrochemical, metallurgy, steel, shipbuilding and other industries.

Slurry Screw Pump Specification

| Product Name | Screw pump |

| Voltage | 220V / 380V |

| Flow | 10~90m3/h |

| Suction Diameter | 3~6 inch |

| Head | 1~ 99m |

| Power | up to 120 kw |

| Material | Cast iron/Stainless Steel(SS304/SS316L/SS904) |

| Warranty | 1 year |

Huatao Pumps Application

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.