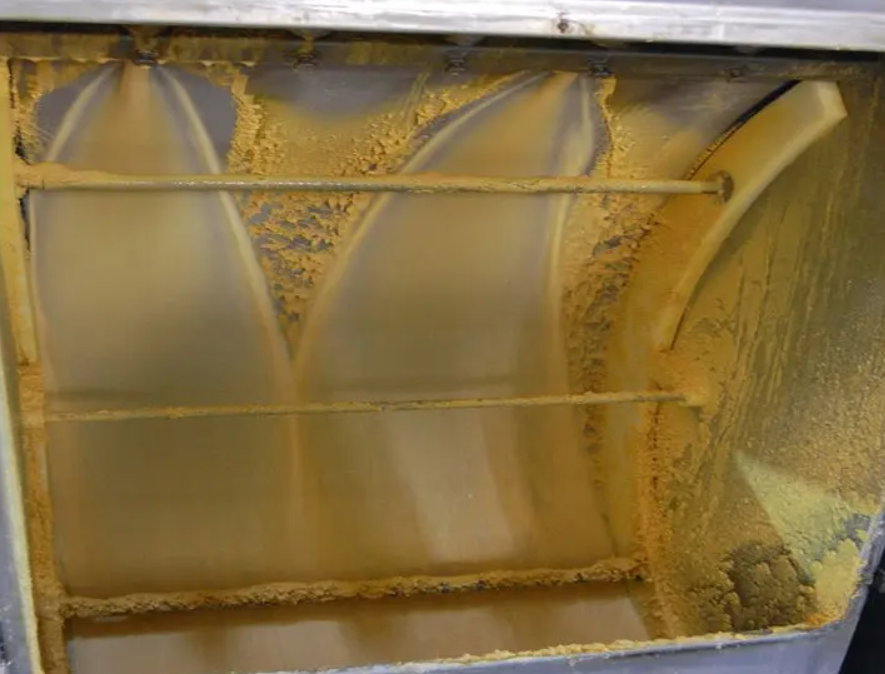

Double Body Pressure Arc Screen

Material:316L

Screen Area:5-8m2 or as request

Screen seam:70um or as request

Screen Capacity:15-30m³/H or as request

Internal screen bend Size:710*1600mm

Description Of Pressure 120° DSM Screens For Corn Starch Process

Pressure 120° DSM screens also called 120° pressure box, Curved screens,Bent screens, DSM Screen, Curved Sieve Bend,etc.The pressure curved screen is primarily used in starch processing for multi-stage countercurrent washing, screening, dewatering, extraction, and removal of solids and impurities. This equipment effectively improves starch yield and quality, making it a crucial piece of equipment in the starch industry. The device screens wet materials using pressure and consists of a screen surface, screen box, feeding device, and discharge port. The screen surface is the key component of the pressure curved screen, assembled from stainless steel wedge-shaped screen bars.

Working Principle Of Pressure 120° DSM Screens For Corn Starch Process

During operation, wet material is sprayed from the nozzle under a pressure of 0.2-0.4 MPa. The high feed jet velocity generates tangential force, and the triangular wedge-shaped bars act as blades, scraping the material into a thin layer. This evenly disperses the water and fine materials, creating a "scraping" effect that facilitates material classification. The entire screen surface is self-cleaning. The screened material is discharged from the upper outlet, and the undersize material enters the slurry outlet.

Feature Of Pressure 120° DSM Screens For Corn Starch Process

1.The pressure curved screen is used for separating fine particles. The slurry is continuously fed onto the V-shaped wire screen surface under pressure. The liquid passes through the screen openings, while the solid particles slide down to the bottom of the screen surface.

2.It offers more efficient fiber separation, can withstand higher flow rates, is more cost-effective than other products,

3.The surface treatment provides better impact resistance. It is suitable for solid-liquid separation, corn wet processing, fine fiber removal in the starch industry, food processing, wastewater purification, etc.

Performance Parameters Of Pressure 120° DSM Screens For Corn Starch Process

1. Screen Surface Arc: 120 degrees or specified arc

2. Screen Slot Width: 50um

3. Screen Slot Deviation: ± 0.02 mm

4. Material Throughput: 100-120 m³/h

5. Working Pressure: 0.2-0.4 MPa

6. Screen Surface Width: 710 mm

7. Opening Area: 1600 × 710 mm 1.136 m²

8. Screen Surface Arc Radius: 762 mm

9. Material: 316L or specified material

10. Service Life: 50um with 8 months, 75um with 10 months, 120um with12 months

can not be empty

The E-mail format is not correct

can not be empty